In this section:

Life Cycle Thinking (LCT) seeks to identify possible improvements to goods and services in the form of lower environmental impacts and reduced use of resources across the whole life of the product, called its whole life cycle. This begins with raw material extraction and conversion, then manufacture and distribution, through to use and consumption. It ends with re-use, recycling of materials, energy recovery and final disposal.

The cosmetics industry is committed to reducing the environmental impact of shampoos in all the stages of their life cycle. The industry is taking its responsibilities seriously and is acting at every step. However, the impact is highest during product use and disposal. This video is aimed at helping everyone understand the small steps that can be taken every day to use shampoo sustainably.

The key aim of Life Cycle Thinking is to avoid shifting an environmental effect from one area to another. This means minimising impacts at one stage of the life cycle, or in a geographic region while helping to avoid increases elsewhere; for example, saving energy during the use phase of a product while, at the same time, not increasing the amount of material needed to provide it.

Why take a life cycle approach?

For many years, reducing environmental impacts focused on production processes, treatment of waste and effluent streams. This remains important. These actions help, for example, to successfully address the issues of reducing air and water pollution from a specific operation. However, this does not necessarily reduce the negative environmental impacts related to the consumption of materials and resources. It also does not account for the shifting of burdens; solving one problem while creating another. Solutions, therefore, may not be the best and may even be counter-productive. Life Cycle Thinking can solve this problem.

A win-win situation

Life Cycle Thinking can help identify opportunities and lead to decisions that help improve environmental performance and provide economic benefits. As well as considering the environmental impacts of the processes within our direct control, attention is also given to the raw materials used, supply chains, product use, the effects of disposal and the possibilities for re-use and recycling. Using this approach demonstrates that a company is taking responsibility for reducing environmental impacts.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is an effective method for providing information about a company's environmental performance, improving its understanding of the environmental impacts of its products and identifying cost savings associated with manufacturing and waste disposal methods. However, we should note that, while LCA is a valuable tool and helps us with useful information; it does not make decisions for us.

LCA identifies the material, energy and waste flows of a product over its entire life-cycle so that the environmental impacts can be determined. It can help companies to identify changes to their operations, including product design, which can lead to environmental benefits and cost savings.

Using LCA, it is possible to evaluate the environmental performance of a product from 'cradle to grave', allowing the most significant environmental impacts associated with it during its lifetime to be considered, i.e., from extracting the raw materials and fuel from the earth through to the product's use and, ultimately, disposal.

There are some environmental impacts and issues which LCA is unable to address. Broadly speaking, LCA does not consider things that cannot be measured and subjective impacts; examples are odour and working conditions. In addition, it does not consider economic or social factors.

The international standard, ISO 14044, defines LCIA as the "phase of life cycle assessment aimed at understanding and evaluating the magnitude and significance of the potential environmental impacts of a product system".

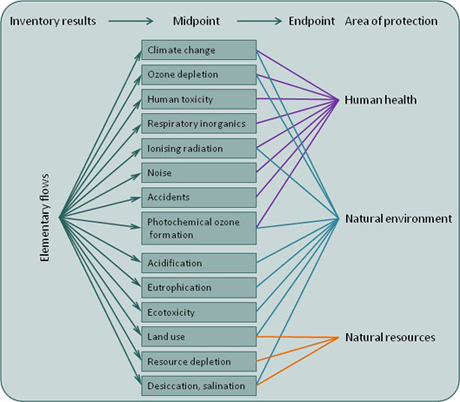

In a LCA, the emissions and resources consumed to make a specific product are compiled and documented in a Life Cycle Inventory (LCI). The resource inputs and emissions (elementary flows) are then classified and characterised to show their significance in a number of environmental impact categories. The following diagram shows how it works:

Once the analysis is complete, the data may be 'modelled', seeing what happens if improvements are made to one area, such as an alternative source for an ingredient. This will check if there are any negative effects in other areas of the model.

Because of the complexity and cost of LCA, it is only really suitable for large companies at the moment.